Untreated water has a high chance of containing harmful bacteria, viruses, and microorganisms that can make people ill when consumed. Drinking water disinfection is one of the trusted processes for making drinking water free from harmful contaminants that can also cause unpleasant tastes and odors.

In large-scale applications such as municipal use, the disinfection of drinking water is a vital public health measure to reduce the spread of diseases and maintain the safety of the people. Water and wastewater treatment companies employ various disinfection technologies, each having its own advantages and disadvantages compared to other processes.

Methods Used By Water and Wastewater Treatment Companies

The World Health Organization (WHO) has provided guidelines and recommendations for managing the hazards that may compromise the safety of public drinking water. They also provided a scientific perspective that national authorities can use in developing regulations and standards appropriate for the local situation.

To ensure the safety of drinking water supplies, multiple barriers are put in place for filtering suspended particles and decontaminating the water in large volumes to ensure the suitability for human consumption.

In water utility plants these multiple treatment barriers include: screening, aeration, flocculation, sedimentation, filtration, disinfection, chlorination, and any supplementary treatment for ensuring the water is free from harmful pathogens. Each of these steps follow standards set by the authorities to ensure the quality of water for its specific use is achieved.

Conventional systems for drinking water disinfection and wastewater treatment are classified into chemical processes and UV radiation. Chemical disinfectants include chlorine gas, chlorine dioxide, sodium hypochlorite, ozone, and peracetic acid. One of the biggest disadvantages of chemical processes is the creation of undesirable disinfection byproducts with potentially significant implications on human health.

Here is an overview of how each disinfection agent is introduced to a water system:

Sodium hypochlorite

Sodium hypochlorite is diluted with water in a tank. The solution is then injected by a pump into the water supply at a controlled rate mixed by a static or mechanical mixer. Sufficient mixing and contact time must be constantly monitored to ensure complete cleansing of pathogens.

Chlorination using sodium hypochlorite is simple and practical in that it does not need extensive technical expertise to operate. This drinking water disinfection system can handle varying water volumes by adjusting the storage and dosing mechanism accordingly.

Ozone

Ozone is an unstable compound which is why it needs to be made on site. The process also requires complex equipment and controls, requiring a huge capital cost to start. Additionally, operation and maintenance are also complicated and costly since the majority of its running cost will need to be allocated to electricity consumption.

UV radiation

The effectiveness of this drinking water disinfection system depends heavily on the lamp’s intensity, water clarity, and the exposure of the microorganisms to the UV light rays. Insufficient energy dosage will not be enough to kill the microorganisms in the water source, leaving it contaminated and unsafe for consumption. Usually, a higher dose than what is needed is produced by the equipment to ensure disinfection requirements are met.

Water and wastewater treatment companies often use a dosing system that consists of a pump, injector, and a tank. The tank contains the liquid solution where it is mixed with water, while the pump maintains control over how much of the mixed solution is distributed into the water system.

All these chemical agents for drinking water disinfection are applicable for small, mid-size, and large-scale tertiary disinfection operations. However, the varying risks for staff, the need for extensive knowledge of technicians, maintenance requirements, and investment and management cost impact which of them is the most appropriate system to use.

For water and wastewater treatment companies, the preferred strategy is to reduce, if not prevent, the entry of pathogens into the water system prior to discharge or distribution. Disinfection is the final treatment process to ensure microbiological contaminants are dealt with immediately before the treated water leaves the water utility plant. This tertiary process is the final key to attaining a water quality that fits the standard set for its respective use, ensuring it will not be harmful to either humans or the environment.

The EPA (Environmental Protection Agency) RWQC (Recreational Water Quality Criteria) has also recommended the use of indicators to assess the presence of microorganisms in water environments. The leading indicator organisms used are Enterococci and E. coli for freshwater sources during a step in the process of drinking water disinfection. Many states and wastewater treatment companies also use the recommended indicators by the EPA RWQC in checking wastewater quality.

Reusing wastewater also has its advantages in improving agricultural production and reducing energy consumption during treatment and distribution. This process also aids in the reduction of regulated nutrient loads to receiving bodies of water.

How Genclean’s Oxidation Technology Helps

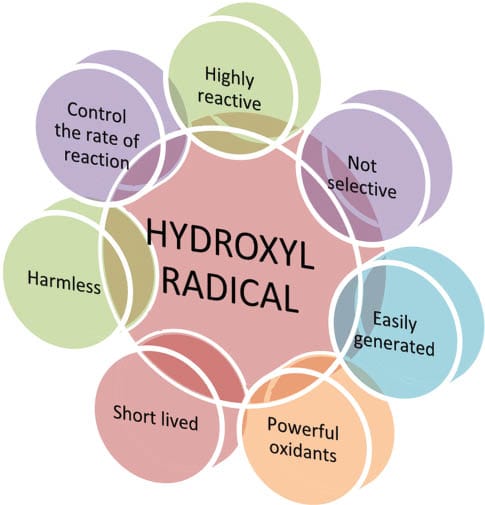

Advanced oxidation process (AOP) is a process that creates and utilizes highly reactive compounds such as reactive oxygen, superoxides, and hydroxyl radicals to oxidize and disinfect contaminants in a water source. It is often applied in the tertiary phase of a water or wastewater treatment process employed by water and wastewater treatment companies. The reason for its implementation is due to its efficiency in treating a wide range of organic and inorganic compounds and microbiological contaminants.

AOP treatment has several advantages over traditional drinking water and wastewater disinfection systems, one of them is the ability to inhibit the creation of disinfection byproducts. However, a major disadvantage though historically has been its high operating cost that limits its integration into mid-range to large-scale water treatment applications.

This is where Genclean’s liquid advanced oxidation treatment products have their major advantages, using scalable advanced oxidation treatment with lower capital and operating costs without disinfection degradation over a conservatively rated 6 month storage life. Our NSF certified sustainable solutions overcome conventional barriers to utilization of an AOP water disinfection process, to serve both water utility plants as well as several industry verticals that require large volumes of water or wastewater to be treated efficiently with relatively lower overall tertiary treatment cost.

Genclean Benefits

Here are the major benefits of using our water and wastewater treatment solutions:

- Genclean’s AOP liquid formula is more effective in its oxidation capability compared to that of ozone, chlorine, hydrogen peroxide, and other non-chlorine disinfecting solutions.

- It is effective in a wide range of pH range, making it a versatile component in the disinfection of water and wastewater products.

- Our products are better than other water treatment formulas because it does not require the activation of an external catalyst.

- Genclean water treatment solutions require little investment when it comes to capital cost and staffing. There is no need to hire a highly trained technician to monitor the stability of the solution when mixed with any water source.

- Distribution of the Genclean liquid AOP product can be managed using a GWT chemical feed pump system with an integrated pH/ORP controller making automated dosing easier and safer.

Our Mission – Make Water Treatment Safer And More Effective

Genclean Treatment Solutions is committed to providing sustainable and scalable liquid solutions for the disinfection and oxidation of harmful microorganisms and pathogens found in a wide variety of water sources. Our NSF-certified advanced oxidation disinfection products are sustainable and non-toxic to humans and the environment.

Our products assist water and wastewater treatment companies in the sectors of food/beverage & aquaculture, water utilities, heavy industry, commercial cooling tower treatment, and hospitality.

Through the innovation and value that our sustainable and scalable advanced oxidation liquid treatment process provides, we make it easier for both private industry and government clients to meet ever changing water & wastewater treatment standards set by local, state, and federal regulatory authorities.

Contact us to know more about Genclean advanced oxidation treatment solutions and learn how we can help you in making your high volume water treatment processes safer, effective, and cost efficient.